WO2012081031A1 - Process for preparing tetrabenazine - Google Patents

Process for preparing tetrabenazine Download PDFInfo

- Publication number

- WO2012081031A1 WO2012081031A1 PCT/IN2011/000247 IN2011000247W WO2012081031A1 WO 2012081031 A1 WO2012081031 A1 WO 2012081031A1 IN 2011000247 W IN2011000247 W IN 2011000247W WO 2012081031 A1 WO2012081031 A1 WO 2012081031A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- structural formula

- compound

- tetrabenazine

- substantially pure

- dimethoxyphenyl

- Prior art date

Links

- WUZNVFUYFDVUIC-UHFFFAOYSA-N COc(ccc(CCNC=O)c1)c1OC Chemical compound COc(ccc(CCNC=O)c1)c1OC WUZNVFUYFDVUIC-UHFFFAOYSA-N 0.000 description 3

- AROIGOIHDJUKKR-UHFFFAOYSA-N CCc(c(C=C)c1)cc(OC)c1OC Chemical compound CCc(c(C=C)c1)cc(OC)c1OC AROIGOIHDJUKKR-UHFFFAOYSA-N 0.000 description 1

- BXSSQIVRPWYUDY-UHFFFAOYSA-N COc(cc(C=NCC1)c1c1)c1OC=O Chemical compound COc(cc(C=NCC1)c1c1)c1OC=O BXSSQIVRPWYUDY-UHFFFAOYSA-N 0.000 description 1

- NSLJVQUDZCZJLK-UHFFFAOYSA-N COc(cc(CCN=C1)c1c1)c1OC Chemical compound COc(cc(CCN=C1)c1c1)c1OC NSLJVQUDZCZJLK-UHFFFAOYSA-N 0.000 description 1

- WNCSGUKOLCEXLF-UHFFFAOYSA-N COc(cc(CCN=C1)c1c1)c1OC=O Chemical compound COc(cc(CCN=C1)c1c1)c1OC=O WNCSGUKOLCEXLF-UHFFFAOYSA-N 0.000 description 1

- ANOUKFYBOAKOIR-UHFFFAOYSA-N COc(ccc(CCN)c1)c1OC Chemical compound COc(ccc(CCN)c1)c1OC ANOUKFYBOAKOIR-UHFFFAOYSA-N 0.000 description 1

- YOOXTMMUFBCZAG-UHFFFAOYSA-N O=COc(cc(CCN=C1)c1c1)c1OC=O Chemical compound O=COc(cc(CCN=C1)c1c1)c1OC=O YOOXTMMUFBCZAG-UHFFFAOYSA-N 0.000 description 1

- XKXDTCVAXLUDME-UHFFFAOYSA-N Oc(cc(C=NCC1)c1c1)c1OC=O Chemical compound Oc(cc(C=NCC1)c1c1)c1OC=O XKXDTCVAXLUDME-UHFFFAOYSA-N 0.000 description 1

- PWCQVMIYUGOTLG-UHFFFAOYSA-N Oc(cc(CCN=C1)c1c1)c1O Chemical compound Oc(cc(CCN=C1)c1c1)c1O PWCQVMIYUGOTLG-UHFFFAOYSA-N 0.000 description 1

- XRZUFTFXVKENJX-UHFFFAOYSA-N Oc(cc(CCN=C1)c1c1)c1OC=O Chemical compound Oc(cc(CCN=C1)c1c1)c1OC=O XRZUFTFXVKENJX-UHFFFAOYSA-N 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D217/00—Heterocyclic compounds containing isoquinoline or hydrogenated isoquinoline ring systems

- C07D217/02—Heterocyclic compounds containing isoquinoline or hydrogenated isoquinoline ring systems with only hydrogen atoms or radicals containing only carbon and hydrogen atoms, directly attached to carbon atoms of the nitrogen-containing ring; Alkylene-bis-isoquinolines

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C233/00—Carboxylic acid amides

- C07C233/01—Carboxylic acid amides having carbon atoms of carboxamide groups bound to hydrogen atoms or to acyclic carbon atoms

- C07C233/16—Carboxylic acid amides having carbon atoms of carboxamide groups bound to hydrogen atoms or to acyclic carbon atoms having the nitrogen atom of at least one of the carboxamide groups bound to a carbon atom of a hydrocarbon radical substituted by singly-bound oxygen atoms

- C07C233/17—Carboxylic acid amides having carbon atoms of carboxamide groups bound to hydrogen atoms or to acyclic carbon atoms having the nitrogen atom of at least one of the carboxamide groups bound to a carbon atom of a hydrocarbon radical substituted by singly-bound oxygen atoms with the substituted hydrocarbon radical bound to the nitrogen atom of the carboxamide group by an acyclic carbon atom

- C07C233/18—Carboxylic acid amides having carbon atoms of carboxamide groups bound to hydrogen atoms or to acyclic carbon atoms having the nitrogen atom of at least one of the carboxamide groups bound to a carbon atom of a hydrocarbon radical substituted by singly-bound oxygen atoms with the substituted hydrocarbon radical bound to the nitrogen atom of the carboxamide group by an acyclic carbon atom having the carbon atom of the carboxamide group bound to a hydrogen atom or to a carbon atom of an acyclic saturated carbon skeleton

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07D—HETEROCYCLIC COMPOUNDS

- C07D471/00—Heterocyclic compounds containing nitrogen atoms as the only ring hetero atoms in the condensed system, at least one ring being a six-membered ring with one nitrogen atom, not provided for by groups C07D451/00 - C07D463/00

- C07D471/02—Heterocyclic compounds containing nitrogen atoms as the only ring hetero atoms in the condensed system, at least one ring being a six-membered ring with one nitrogen atom, not provided for by groups C07D451/00 - C07D463/00 in which the condensed system contains two hetero rings

- C07D471/04—Ortho-condensed systems

Definitions

- Chemically tetrabenazine is cis rac -1, 3, 4, 6, 7, 1 lb-hexahydro-9, 10-dimethoxy-3-(2- methylpropyl)-2Hbenzo[a]quinolizin-2-one and it is represented by compound of structural formula I.

- tetrabenazine The proprietary name of tetrabenazine is Xenazine and is marketed by Biovail Americas. Xenazine is indicated for the treatment of chorea associated with Huntington's disease.

- U.S. patent no. 2,830,993 discloses a process for the preparation of tetrabenazine compound of structural formula I wherein 1 -carbethoxymethyl-6, 7-dimethoxy-l , 2, 3, 4- tetrahydroisoquinoline compound of structural formula IV is being reacted with mono- isobutylmalonic acid dimethyl ester compound of structural formula V and paraformaldehyde in methanol solvent to get l-carbethoxymethyl-2 (2, 2-dicarbomethoxy-4-methyl-n-pentyl)-6, 7- dimethoxy-1, 2, 3, 4-tetrahydroisoquinoline compound of structural formula VI.

- the 1- carbethoxymethyl-2(2,2-dicarbomethoxy-4-methyl-n-pentyl)-6,7-dimethoxy-l ,2,3,4- tetrahydroisoquinoline compound of structural formula VI is subjected to Dieckmann cyclization , hydrolysis and decarboxylation to get tetrabenazine compound of structural formula I, which is recrystallized from di-isopropyl ether solvent.

- U. S. patent no. 4,678,792 discloses a process for the preparation of 6, 7-dimethoxy-3, 4- dihydroisoquinoline compound of structural formula VII wherein 2-(3, 4-dimethoxyphenyl)- ethylamine compound of structural formula II is being reacted with chloral hydrate at 120°C to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III.

- the N- formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III is further reacted with polyphosphoric acid to get 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

- the 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII is being used as an intermediate for the preparation of tetrabenazine compound of structural formula I.

- U.S. patent publication no. 2010/0130480 discloses a process for the preparation of 6, 7- dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII by reacting 2-(3, 4- dimethoxyphenyl)-ethylamine compound of structural formula II with hexamethylenetetramine in presence of acetic acid or trifluoroacetic acid.

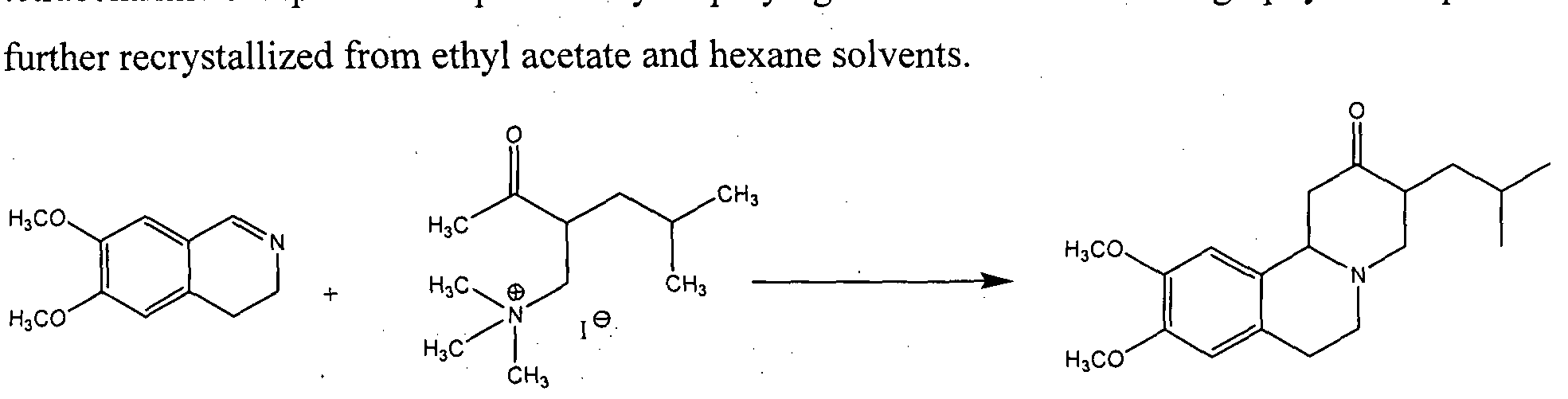

- U.S. patent publication no. 2008/0167337 discloses a process for the preparation of tetrabenazine compound of structural formula I wherein 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII is reacted with 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide compound of structural formula VIII to get crude tetrabenazine compound.

- the crude tetrabenazine compound was purified by employing flash column chromatography technique and

- Tetrabenazine in aqueous medium poses a challenge, since the bioavailability of a water insoluble active ingredient, like Tetrabenazine, is usually poor.

- active pharmaceutical ingredients with a high surface area to obtain formulations with greater bioavailability.

- Tetrabenazine compound of structural formula I with defined particle size distribution which are interlinked and has effect on the solubility and bioavailability.

- a first object of the present invention is to provide a process for the preparation of tetrabenazine compound of structural formula I comprises formylating 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)- ethylamine compound of structural formula III and converting N-formyl-2-(3, 4- dimethoxyphenyl)-ethylamine compound of structural formula III into tetrabenazine compound of structural formula I.

- a second object of the present invention is to provide a process for the preparation of 6, 7- dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII comprises the steps of: a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III and

- a third object of the present invention is to provide a process for the preparation of tetrabenazine compound of structural formula I comprising the steps of:

- a further object of the present invention is to provide a process for the preparation of crystalline tetrabenazine compound of structural formula I comprising the steps of:

- a further object of the present invention is to provide a process for the preparation of substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII comprising the steps of:

- a further object of the present invention is to provide crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by X-ray diffraction pattern as depicted by figure no. 1.

- a further object of the present invention is to provide crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by DSC thermogram as depicted by figure no. 2.

- a further object of the present invention is to provide crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by TGA thermogram as depicted by figure no. 3.

- a further object of the present invention is to provide a process of preparing crystalline form A of substantially pure tetrabenazine compound of structural formula I comprises recrystallization of tetrabenazine compound of structural formula I in an alcoholic solvents.

- a further object of the present invention is to provide a pharmaceutical composition

- a pharmaceutical composition comprising crystalline form A of substantially pure tetrabenazine compound of structural formula I and pharmaceutically acceptable carrier.

- a further object of the present invention is to provide substantially pure N-formyl-2-(3, 4- dimethoxyphenyl)-ethylamine compound of structural formula III having less than 0.1% weight / weight of following compounds of structural formula XVII to XXII.

- a further object of the present invention is to provide substantially pure 6, 7-dimethoxy-3, 4- dihydroisoquinoline compound of structural formula VII having less than 0.1 % weight / weight of following compounds of structural formula IX, X, XXIII, XXIV, XXV and XXVI

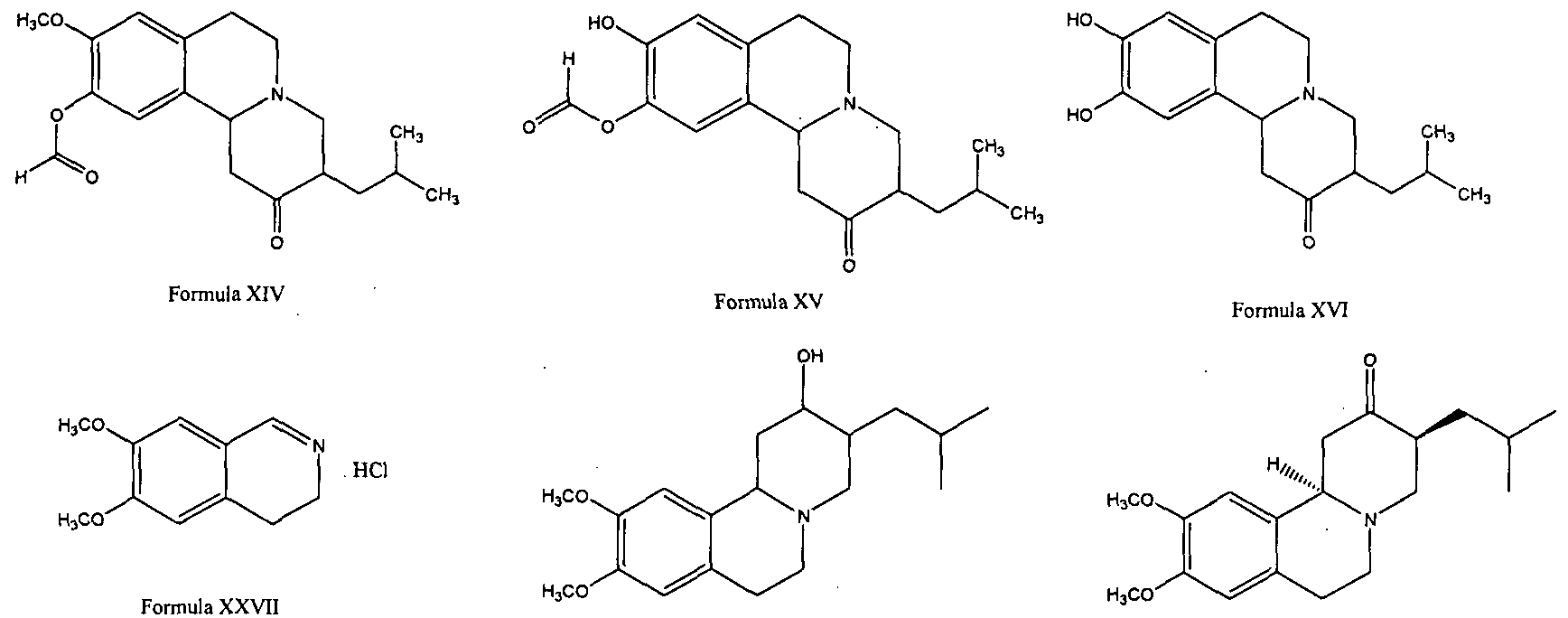

- a further object of the present invention is to provide substantially pure tetrabenazine compound of structural formula I having less than 0.15% weight / weight of compounds of structural formula XI, XII, XIII, XIV, XV, XVI, XXVII, XXVIII and XXIX.

- the compound of structural formula XXIX represents trans isomer of tetrabenazine.

- a further object of the present invention is to provide substantially pure tetrabenazine compound of structural formula I having less than 0.15% weight / weight of compounds of structural formula XXVII, XXVIII and XXIX.

- a further object of the present invention is to provide tetrabenazine compound of structural formula I having equals to or more than 99.5 % purity as determined by HPLC technique, bulk density in the range of O. lOgm/ml to 0.60gm/ml, tapped density in the range of 0.30 gm/ml to 0.70 gm/ml, surface area in the range of 2.0 m 2 /gm to 6.0 m 2 /gm or d90 equals to or less than 50 ⁇ .

- a further object of the present invention is to provide pharmaceutical composition comprises tetrabenazine compound of structural formula I having tapped density in the range of 0.30 gm ml to 0.70 gm/ml and optionally one or more other substances such as pharmaceutical excipients.

- a further object of the present invention is to provide pharmaceutical composition comprises tetrabenazine compound of structural formula I having d90 equals to or less than 50 ⁇ and optionally one or more other substances such as pharmaceutical excipients.

- a further object of the present invention is to provide tetrabenazine compound of structural formula I having bulk density in the range of O. lOgm/ml to 0.60gm/ml, tapped density in the range of 0.30 gm / ml to 0.70 gm/ml, surface area in the range of 2.0 m 2 /gm to 6.0 m 2 /gm or d90 equals to or less than 50 ⁇ .

- the formylation of 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid may be carried out in an aromatic hydrocarbon solvents.

- the formic acid may be used as such or as a solution of formic acid in water.

- the concentration of formic acid in water may be in the range of 75% weight / weight to 99% weight / weight.

- an aromatic hydrocarbon solvent may be selected from the group comprising of toluene, o-xylene, p-xylene or mixture(s) thereof.

- the formylation of 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid may be carried out for a period of 2 hours to 10 hours at a temperature in the range of 40°C to 150°C.

- the substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III may be isolated by concentrating the reaction mass under reduced pressure.

- substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III refer to N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound having less than 0.15% weight / weight of following compounds of structural formula XVII to XXII.

- the substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III may be converted into tetrabenazine compound of structural formula I by first converting substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII and then converting substantially pure 6, 7-dimethoxy-3, 4- dihydroisoquinoline compound of structural formula VII into tetrabenazine compound of structural formula I.

- the substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III may be reacted with polyphosphoric acid to get a substantially pure 6, 7-dimethoxy- 3, 4-dihydroisoquinoline compound of structural formula VII.

- reaction of substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III with polyphosphoric acid may be carried out in an aromatic hydrocarbon solvents.

- the aromatic hydrocarbon solvent may be selected from the group comprising of toluene, o- xylene, p-xylene or mixture (s) thereof.

- reaction of substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III with polyphosphoric acid may be carried out for a period of 3 hours to 8 hours at a temperature in the range of 80°C to 180°C.

- the concentration of polyphosphoric acid may be in the range of 75% weight /weight to 85% weight / weight.

- the substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII may be isolated by quenching the reaction mass with water followed by extraction with an alkyl acetate solvent at a pH in the range of 8 to 12.

- the examples of an alkyl acetate solvent may be selected from the group comprising of methyl acetate, ethyl acetate, n-propyl acetate, isopropyl acetate, n-butyl acetate, isobutyl acetate or mixture(s) thereof.

- the pH of quenching reaction mass may be adjusted by an aqueous solution of an alkali metal hydroxide.

- alkali metal hydroxide may be selected from the group comprising of sodium hydroxide, potassium hydroxide or lithium hydroxide.

- the concentration of an aqueous solution of alkali metal hydroxide may be in the range of 10% weight / weight to 100% weight / weight.

- the substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII may be isolated by concentrating the reaction mass under reduced pressure.

- substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII refer to 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound having less than 0.15% weight / weight of following compounds of structural formula IX, X,

- VIII may be prepared by methods known in the art such as those are described in U.S. patent publication no. 2008/0167337 and 2010/0130480, which are incorporated herein by reference only.

- reaction of substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII with 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide compound of structural formula VIII may be carried out in an alcoholic solvents.

- an alcoholic solvent may be selected from the group comprising of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, tertiary butanol, n-pentanol or mixture(s) thereof.

- the volume of alcohol solvent may be in the range of 3 volumes / weight to 15 volumes / weig with respect to 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

- the alcoholic solvents may contain water in the range of 0 to 20% weight / weight.

- reaction of substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII with 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide compound of structural formula VIII may be carried out for a period of 8 hours to 20 hours at a temperature in the range of 35°C to 120°C.

- the tetrabenazine compound of structural formula I may be isolated by filtering the reaction mass followed by concentrating the filtrate under reduced pressure to get a crude tetrabenazine compound of structural formula I.

- the crude tetrabenazine compound of structural formula I may contain up to 2.5% weight / weight of following compounds of structural formula XXVII, XXVIII and XXIX.

- the crude tetrabenazine compound of structural formula I may be further purified by treating the solution of crude tetrabenazine compound of structural formula I in an organic solvent with an aqueous solution of an alkali metal hydroxide, followed by washing the organic layer with water, concentrating the organic layer under reduced pressure and treating with an alcoholic solvents.

- the organic solvent may be selected from the group comprising of ethers or halogenated hydrocarbons.

- ether solvents may be selected from the group comprising of diethyl ether, n- propyl ether, n-butyl ether, methyl ethyl ether, methyl tertiary butyl ether, diisopropyl ether or mixture(s) thereof.

- halogenated hydrocarbon solvents may be selected from the group comprising of dichloromethane, dichloroethane, carbon tetrachloride or chloroform.

- the solution of crude tetrabenazine compound of structural formula I in an organic solvent may be prepared by dissolving crude tetrabenazine compound of structural formula I in an organic solvent at a temperature in the range of 25°C to 30°C.

- the volume of organic solvent may be in the range of 10 volumes / weight to 50 volumes / weight with respect to crude tetrabenazine.

- the solution of crude tetrabenazine compound of structural formula I in an organic solvent may be treated with an aqueous solution of an alkali metal hydroxide at a temperature in the range of 25°C to 30°C for a period of 15 minutes to 2 hours and then organic layer may be isolated.

- alkali metal hydroxide may be selected from the group comprising of sodium hydroxide, potassium hydroxide, lithium hydroxide.

- the organic layer may be washed with water at a temperature in the range of 25°C to 30°C.

- the organic layer may be concentrate under reduced pressure and then the resulting residue may be treated with an alcoholic solvent.

- an alcoholic solvent may be selected from the group comprising of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, tertiary butanol, n-pentanol or mixture(s) thereof.

- the volume of alcohol solvent may be in the range of 2 volumes / weight to 20 volumes / weight with respect to tetrabenazine.

- the solution of residue in an alcoholic solvent may be treated with an activated charcoal for a period of 30 minutes to 4 hours at a temperature in the range of 40°C to 65°C.

- the substantially pure crystalline form A of tetrabenazine compound of structural formula I may be isolated by the steps of filtration, washing, centrifugation, drying and combination thereof.

- substantially pure tetrabenazine described herein refer to tetrabenazine compound having less than 0.15% weight / weight of compounds of structural formula XI, XII, XIII, XIV, XV, XVI, XXVII, XXVIII and XXIX.

- Powder X-ray diffraction pattern having peaks at 6.4, 10.7, 12.1 , 12.9, 14.3, 19.8, 22.2 and 23.2 ⁇ 0.2° 2 ⁇ .

- E. d90 equals to or less than 50 ⁇ .

- the crystalline form A of substantially pure tetrabenazine compound of structural formula I may be characterized by DSC endotherm at about 129.14°C ⁇ 5°C.

- the crystalline form A of substantially pure tetrabenazine compound of structural formula I may be anhydrous in nature as depicted by TGA thermogram by figure no. 3.

- PSD particle size distribution

- Specific surface area is defined in units of square meters per gram (m 2 /gm). It is usually measured by nitrogen absorption analysis. In this analysis, nitrogen is absorbed on the surface of the substance. The amount of the absorbed nitrogen (as measured during the absorption or the subsequent desorption process) is related to the surface area via a formula known as the Brunauer Emmet Teller (B.E.T) formula.

- B.E.T Brunauer Emmet Teller

- ⁇ refers to "micrometer” which is lx 10 "6 meter.

- the tetrabenazine obtained from the present invention may be milled, sifted and / or micronized.

- the crystalline form A of substantially pure tetrabenazine compound of structural formula I obtained from the present invention may be milled, sifted and / or micronized.

- the crystalline form A of substantially pure tetrabenazine compound of structural formula I of defined particle size i.e. d90 equals to or less than 50 ⁇ may be produced by milling of a feedstock material and sorting of the milled material by size.

- the crystalline form A of substantially pure tetrabenazine compound of structural formula I may be multimilled through 0.5mm mesh sieve and may be sifted through 40 mesh sieve.

- the pharmaceutical composition of substantially pure crystalline form A of Tetrabenazine compound of structural formula I obtained by the present invention may be formulated into solid dosage forms for administration to humans.

- the solid dosage forms of substantially pure crystalline form A of Tetrabenazine compound of structural formula I may be oral tablets having 12.5mg and 25mg strength.

- the solid dosage forms of substantially pure crystalline form A of Tetrabenazine compound of structural formula I may contain excipients selected from the group comprising of lactose, maize starch, talc, yellow iron oxide or magnesium stearate.

- Tetrabenazine The particle size distribution of Tetrabenazine may be determined by laser diffraction method.

- Dispersant Name Dry dispersion

- Tetrabenazine compound of structural formula I was measured by high performance liquid chromatography equipped with quaternary gradient pumps, variable wavelength UV detector attached with data recorder and integrator software under the following conditions:

- Rinse/wash solvent Mixture of 20 volumes of water and 80 volumes of acetonitrile

- Mobile phase-A Dibasic phosphate buffer solution (0.01M)

- Mobile phase-B A mixture of acetonitrile and methanol

- Step 1 Process for the preparation of N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine

- Step 2 Process for the preparation of 6, 7-dimethoxy-3, 4-dihydroisoquinoline

- Stage B Process for the preparation of 3-((dimethylamino) methyi)-5-methylhexan-2-one methiodide

- Step 1 Process for the preparation of 3-((dimethylamino) methyl)-5-methylhexan-2-one

- Dimethylamine hydrochloride (180gm) and paraformaldehyde (lOOgm) were added to a solution of 5-methylhexan-2-one (900ml) in methanol (1600ml).

- the resulting reaction mass was heated at reflux for 12 hours, and then the pH was adjusted to about 8.75 with aqueous solution of sodium hydroxide [sodium hydroxide(90gm) + water (900ml)] at 25 °C.

- the resulting reaction solution was extracted by toluene (2x1234ml).

- the organic layer was dried over anhydrous sodium sulfate (50gm) and concentrated under reduced pressure to get title compound.

- Step 2 Process for the preparation of 3-((dimethylamino) methyl)-5-methylhexan-2-one methiodide

- Methyl iodide (323gm) was added dropwise to a solution of 3-((dimethylamino) methyl)-5- methylhexan-2-one (195gm) obtained from step 1 , in ethyl acetate (1650ml) at 25-30°C in 30 minutes.

- the resulting reaction mixture was stirred at 25 °C for 12 hours and then the resulting solids were filtered, washed with water (200ml) and suck-dried to get wet compound (400gm).

- the wet compound was slurried with water (1000ml) at 25°C for 1 hour and then it was again filtered, washed with water (200ml) and dried at 45-50°C to get title compound

- the organic layer was separated, washed with water (3 x 1000ml) and concentrated under reduced pressure to obtain residue.

- the residue was dissolved in methanol (300ml) at 50°C, and resulting solution was treated with an activated carbon (20gm) at 50-60°C for 30minutes and then it was filtered and filtrate was further stirred at 20-25°C for 2 hours.

- the resulting solids were filtered, washed with methanol (150ml), dried at 50-55°C for 8 hours.

- the resulting solids were milled, sifted through 40 mesh sieve and micronized.

Abstract

A substantially pure crystalline form A of tetrabenazine compound of structural formula I and processes for the preparation thereof is provided.

Description

PROCESS FOR PREPARING TETRABENAZINE

FIELD OF THE INVENTION

The present invention relates to a process for preparing tetrabenazine compound of structural formula I comprises formylating 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III and converting N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into tetrabenazine compound of structural formula I.

Formula II Formula III Formula I

BACKGROUND OF THE INVENTION:

Chemically tetrabenazine is cis rac -1, 3, 4, 6, 7, 1 lb-hexahydro-9, 10-dimethoxy-3-(2- methylpropyl)-2Hbenzo[a]quinolizin-2-one and it is represented by compound of structural formula I.

Formula 1

The proprietary name of tetrabenazine is Xenazine and is marketed by Biovail Americas. Xenazine is indicated for the treatment of chorea associated with Huntington's disease.

U.S. patent no. 2,830,993 discloses a process for the preparation of tetrabenazine compound of structural formula I wherein 1 -carbethoxymethyl-6, 7-dimethoxy-l , 2, 3, 4- tetrahydroisoquinoline compound of structural formula IV is being reacted with mono- isobutylmalonic acid dimethyl ester compound of structural formula V and paraformaldehyde in methanol solvent to get l-carbethoxymethyl-2 (2, 2-dicarbomethoxy-4-methyl-n-pentyl)-6, 7- dimethoxy-1, 2, 3, 4-tetrahydroisoquinoline compound of structural formula VI. The 1- carbethoxymethyl-2(2,2-dicarbomethoxy-4-methyl-n-pentyl)-6,7-dimethoxy-l ,2,3,4- tetrahydroisoquinoline compound of structural formula VI is subjected to Dieckmann cyclization , hydrolysis and decarboxylation to get tetrabenazine compound of structural formula I, which is recrystallized from di-isopropyl ether solvent.

Formula I

Scheme I

U. S. patent no. 4,678,792 discloses a process for the preparation of 6, 7-dimethoxy-3, 4- dihydroisoquinoline compound of structural formula VII wherein 2-(3, 4-dimethoxyphenyl)- ethylamine compound of structural formula II is being reacted with chloral hydrate at 120°C to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III. The N- formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III is further reacted with polyphosphoric acid to get 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of

structural formula VII. The 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII is being used as an intermediate for the preparation of tetrabenazine compound of structural formula I.

Formula III

Formula II

Polyphosphoric acid

Formula VII

Scheme II

Bull. Korean Chem. Soc. 2002 Volume (23). No. l , page no. 149 discloses N-formylation of various amines and alcohols with formic acid in toluene.

U.S. patent publication no. 2010/0130480 discloses a process for the preparation of 6, 7- dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII by reacting 2-(3, 4- dimethoxyphenyl)-ethylamine compound of structural formula II with hexamethylenetetramine in presence of acetic acid or trifluoroacetic acid.

Formula II Formula VII

U.S. patent publication no. 2008/0167337 discloses a process for the preparation of tetrabenazine compound of structural formula I wherein 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII is reacted with 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide

compound of structural formula VIII to get crude tetrabenazine compound. The crude tetrabenazine compound was purified by employing flash column chromatography technique and

Formula VIII Formula I

The prior-art processes for preparing N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III produces below mentioned compound of structural formula XVII, XVIII, XIX, XX, XXI and XXII as a by-product of the reaction due to the demethylation and formylation of resulting hydroxy compounds.

Formula XX Formula XXI Formula XXII

The compounds of structural formula XVII, XVIII, XIX, XX, XXI and XXII are being carry- forwarded into the further steps of reactions of preparing tetrabenazine compound of structural formula I and therefore there is a need in the art to develop an improved process of preparing 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII, which obviates the prior-art problems.

Accordingly there is provided a process of preparing tetrabenazine compound of structural formula I wherein 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII is being formed without the formation of above mentioned compounds of structural formula XVII, XVIII, XIX, XX, XXI and XXII.

The lack of solubility of Tetrabenazine in aqueous medium poses a challenge, since the bioavailability of a water insoluble active ingredient, like Tetrabenazine, is usually poor. Thus there is a need in the art to prepare active pharmaceutical ingredients with a high surface area to obtain formulations with greater bioavailability. In view of the foregoing, there is a need in the art to obtain Tetrabenazine compound of structural formula I with defined particle size distribution which are interlinked and has effect on the solubility and bioavailability.

Accordingly it is an object of the present invention to solve the problems associated with the prior art and provides an efficient process. The process provides obvious benefits with respect to economics and convenience to operate on a commercial scale.

OBJECT OF THE INVENTION:

A first object of the present invention is to provide a process for the preparation of tetrabenazine compound of structural formula I comprises formylating 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)- ethylamine compound of structural formula III and converting N-formyl-2-(3, 4- dimethoxyphenyl)-ethylamine compound of structural formula III into tetrabenazine compound of structural formula I.

Formula II Formula III Formula I

A second object of the present invention is to provide a process for the preparation of 6, 7- dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII comprises the steps of: a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III and

Formula II Formula III

b. converting N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

Formula III Formula VII

A third object of the present invention is to provide a process for the preparation of tetrabenazine compound of structural formula I comprising the steps of:

a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural

Formula II Formula III

b. converting N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII and

Formula III Formula VII

c. converting 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII into tetrabenazine compound of structural formula I.

A further object of the present invention is to provide a process for the preparation of crystalline tetrabenazine compound of structural formula I comprising the steps of:

a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III,

Formula II Formula III

b. converting N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII,

Formula III Formula VII

c. converting 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII into tetrabenazine compound of structural formula I and

Formula VII

d. isolating crystalline tetrabenazine compound of structural formula I.

A further object of the present invention is to provide a process for the preparation of substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII comprising the steps of:

a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III and

Formula II Formula III

b. converting substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

Formula 111 Formula VI]

A further object of the present invention is to provide crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by X-ray diffraction pattern as depicted by figure no. 1.

A further object of the present invention is to provide crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by DSC thermogram as depicted by figure no. 2.

A further object of the present invention is to provide crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by TGA thermogram as depicted by figure no. 3.

A further object of the present invention is to provide a process of preparing crystalline form A of substantially pure tetrabenazine compound of structural formula I comprises recrystallization of tetrabenazine compound of structural formula I in an alcoholic solvents.

A further object of the present invention is to provide a pharmaceutical composition comprising crystalline form A of substantially pure tetrabenazine compound of structural formula I and pharmaceutically acceptable carrier.

A further object of the present invention is to provide substantially pure N-formyl-2-(3, 4- dimethoxyphenyl)-ethylamine compound of structural formula III having less than 0.1% weight / weight of following compounds of structural formula XVII to XXII.

A further object of the present invention is to provide substantially pure 6, 7-dimethoxy-3, 4- dihydroisoquinoline compound of structural formula VII having less than 0.1 % weight / weight of following compounds of structural formula IX, X, XXIII, XXIV, XXV and XXVI

A further object of the present invention is to provide substantially pure tetrabenazine compound of structural formula I having less than 0.15% weight / weight of compounds of structural formula XI, XII, XIII, XIV, XV, XVI, XXVII, XXVIII and XXIX.

A further object of the present invention is to provide substantially pure tetrabenazine compound of structural formula I having less than 0.15% weight / weight of compounds of structural formula XXVII, XXVIII and XXIX.

A further object of the present invention is to provide tetrabenazine compound of structural formula I having equals to or more than 99.5 % purity as determined by HPLC technique, bulk density in the range of O. lOgm/ml to 0.60gm/ml, tapped density in the range of 0.30 gm/ml to 0.70 gm/ml, surface area in the range of 2.0 m2/gm to 6.0 m2/gm or d90 equals to or less than 50μηι.

A further object of the present invention is to provide pharmaceutical composition comprises substantially pure tetrabenazine compound of structural formula I having more than 99.5 % purity as determined by HPLC technique and optionally one or more other substances such as pharmaceutical excipients.

A further object of the present invention is to provide pharmaceutical composition comprises tetrabenazine compound of structural formula I having bulk density in the range of O.lOgm/ml to 0.60gm/ml and optionally one or more other substances such as pharmaceutical excipients.

A further object of the present invention is to provide pharmaceutical composition comprises tetrabenazine compound of structural formula I having tapped density in the range of 0.30 gm ml to 0.70 gm/ml and optionally one or more other substances such as pharmaceutical excipients.

A further object of the present invention is to provide pharmaceutical composition comprises tetrabenazine compound of structural formula I having d90 equals to or less than 50μπι and optionally one or more other substances such as pharmaceutical excipients.

A further object of the present invention is to provide pharmaceutical composition comprises tetrabenazine compound of structural formula I having surface area in the range of 2.0 m2/gm to 6.0 m2/gm and optionally one or more other substances such as pharmaceutical excipients.

A further object of the present invention is to provide tetrabenazine compound of structural formula I having bulk density in the range of O. lOgm/ml to 0.60gm/ml, tapped density in the range of 0.30 gm / ml to 0.70 gm/ml, surface area in the range of 2.0 m2/gm to 6.0 m2/gm or d90 equals to or less than 50μηι.

DETAIL DESCRIPTION OF THE INVENTION:

The formylation of 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid may be carried out in an aromatic hydrocarbon solvents.

The formic acid may be used as such or as a solution of formic acid in water.

The concentration of formic acid in water may be in the range of 75% weight / weight to 99% weight / weight.

The examples of an aromatic hydrocarbon solvent may be selected from the group comprising of toluene, o-xylene, p-xylene or mixture(s) thereof.

The formylation of 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid may be carried out for a period of 2 hours to 10 hours at a temperature in the range of 40°C to 150°C.

The substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III may be isolated by concentrating the reaction mass under reduced pressure.

The term "substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III" described herein refer to N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound having less than 0.15% weight / weight of following compounds of structural formula XVII to XXII.

The limit of detection and limit of quantitation for compounds of structural formula XVII to XXII in compound of structural formula III are as follows:

The substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III may be converted into tetrabenazine compound of structural formula I by first converting substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII and then converting substantially pure 6, 7-dimethoxy-3, 4- dihydroisoquinoline compound of structural formula VII into tetrabenazine compound of structural formula I.

The substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III may be reacted with polyphosphoric acid to get a substantially pure 6, 7-dimethoxy- 3, 4-dihydroisoquinoline compound of structural formula VII.

The reaction of substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III with polyphosphoric acid may be carried out in an aromatic hydrocarbon solvents.

The aromatic hydrocarbon solvent may be selected from the group comprising of toluene, o- xylene, p-xylene or mixture (s) thereof.

The reaction of substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III with polyphosphoric acid may be carried out for a period of 3 hours to 8 hours at a temperature in the range of 80°C to 180°C.

The concentration of polyphosphoric acid may be in the range of 75% weight /weight to 85% weight / weight.

The substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII may be isolated by quenching the reaction mass with water followed by extraction with an alkyl acetate solvent at a pH in the range of 8 to 12.

The examples of an alkyl acetate solvent may be selected from the group comprising of methyl acetate, ethyl acetate, n-propyl acetate, isopropyl acetate, n-butyl acetate, isobutyl acetate or mixture(s) thereof.

The pH of quenching reaction mass may be adjusted by an aqueous solution of an alkali metal hydroxide.

The examples of an alkali metal hydroxide may be selected from the group comprising of sodium hydroxide, potassium hydroxide or lithium hydroxide.

The concentration of an aqueous solution of alkali metal hydroxide may be in the range of 10% weight / weight to 100% weight / weight.

The substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII may be isolated by concentrating the reaction mass under reduced pressure.

The term "substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII" described herein refer to 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound having less than 0.15% weight / weight of following compounds of structural formula IX, X,

XXIII, XXIV, XXV and XXVI

The limit of detection and limit of quantitation for compounds of structural formula IX, X, XXIII, XXIV, XXV and XXVI in compound of structural formula VII are as follows:

The substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula

VII may be reacted with 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide compound of structural formula VIII to get a tetrabenazine compound of structural formula I.

The 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide compound of structural formula

VIII may be prepared by methods known in the art such as those are described in U.S. patent publication no. 2008/0167337 and 2010/0130480, which are incorporated herein by reference only.

The reaction of substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII with 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide compound of structural formula VIII may be carried out in an alcoholic solvents.

The examples of an alcoholic solvent may be selected from the group comprising of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, tertiary butanol, n-pentanol or mixture(s) thereof.

The volume of alcohol solvent may be in the range of 3 volumes / weight to 15 volumes / weig with respect to 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

The alcoholic solvents may contain water in the range of 0 to 20% weight / weight.

The reaction of substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII with 3-dimethylaminomethyl-5-methyl-hexan-2-one methiodide compound of structural formula VIII may be carried out for a period of 8 hours to 20 hours at a temperature in the range of 35°C to 120°C.

The tetrabenazine compound of structural formula I may be isolated by filtering the reaction mass followed by concentrating the filtrate under reduced pressure to get a crude tetrabenazine compound of structural formula I.

The crude tetrabenazine compound of structural formula I may contain up to 2.5% weight / weight of following compounds of structural formula XXVII, XXVIII and XXIX.

The crude tetrabenazine compound of structural formula I may be further purified by treating the solution of crude tetrabenazine compound of structural formula I in an organic solvent with an aqueous solution of an alkali metal hydroxide, followed by washing the organic layer with water, concentrating the organic layer under reduced pressure and treating with an alcoholic solvents.

The organic solvent may be selected from the group comprising of ethers or halogenated hydrocarbons.

The examples of ether solvents may be selected from the group comprising of diethyl ether, n- propyl ether, n-butyl ether, methyl ethyl ether, methyl tertiary butyl ether, diisopropyl ether or mixture(s) thereof.

The examples of halogenated hydrocarbon solvents may be selected from the group comprising of dichloromethane, dichloroethane, carbon tetrachloride or chloroform.

The solution of crude tetrabenazine compound of structural formula I in an organic solvent may be prepared by dissolving crude tetrabenazine compound of structural formula I in an organic solvent at a temperature in the range of 25°C to 30°C.

The volume of organic solvent may be in the range of 10 volumes / weight to 50 volumes / weight with respect to crude tetrabenazine.

The solution of crude tetrabenazine compound of structural formula I in an organic solvent may be treated with an aqueous solution of an alkali metal hydroxide at a temperature in the range of 25°C to 30°C for a period of 15 minutes to 2 hours and then organic layer may be isolated.

The examples of an alkali metal hydroxide may be selected from the group comprising of sodium hydroxide, potassium hydroxide, lithium hydroxide.

The organic layer may be washed with water at a temperature in the range of 25°C to 30°C.

The organic layer may be concentrate under reduced pressure and then the resulting residue may be treated with an alcoholic solvent.

The examples of an alcoholic solvent may be selected from the group comprising of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, tertiary butanol, n-pentanol or mixture(s) thereof.

The volume of alcohol solvent may be in the range of 2 volumes / weight to 20 volumes / weight with respect to tetrabenazine.

The solution of residue in an alcoholic solvent may be treated with an activated charcoal for a period of 30 minutes to 4 hours at a temperature in the range of 40°C to 65°C.

The solution of residue in an alcoholic solvent may be cooled to 25°C and substantially pure crystalline form A of tetrabenazine compound of structural formula I may be isolated.

The substantially pure crystalline form A of tetrabenazine compound of structural formula I may be isolated by the steps of filtration, washing, centrifugation, drying and combination thereof.

The term "substantially pure tetrabenazine" described herein refer to tetrabenazine compound having less than 0.15% weight / weight of compounds of structural formula XI, XII, XIII, XIV, XV, XVI, XXVII, XXVIII and XXIX.

The limit of detection and limit of quantitation for compounds of structural formula XI, XII, XIII, XIV, XV, XVI, XXVII, XXVIII and XXIX in Tetrabenazine compound of structural formula I are as follows:

The crystalline form A of substantially pure tetrabenazine compound of structural formula I may be characterized by X-ray diffraction pattern having following peaks:

The crystalline form A of substantially pure tetrabenazine compound of structural formula I may be further characterized by following analytical data:

A. Powder X-ray diffraction pattern having peaks at 6.4, 10.7, 12.1 , 12.9, 14.3, 19.8, 22.2 and 23.2 ± 0.2° 2Θ.

B. Bulk density in the range of O. lOgm/ml to 0.60gm/ml.

C. Tapped density in the range of 0.30 gm/ml to 0.70 gm/ml.

D. Surface area in the range of 2.0 m /gm to 6.0 m /gm.

E. d90 equals to or less than 50μηι.

The crystalline form A of substantially pure tetrabenazine compound of structural formula I may be characterized by DSC endotherm at about 129.14°C ± 5°C.

The crystalline form A of substantially pure tetrabenazine compound of structural formula I may be anhydrous in nature as depicted by TGA thermogram by figure no. 3.

The term "particle size distribution (PSD) " described herein means the cumulative volume size distribution of equivalent spherical diameters as determined by laser diffraction at 1 bar dispersive pressure in a Sympatec Helos equipment.

dlO, as used herein is defined as the particle size at which the cumulative percentage undersize is 10 (i.e. the bottom 10% of particles are less than or equal to the stated size); d50 means the median particle size; d90 is defined as the particle size at which the cumulative percentage undersize is 90 (i.e. the bottom 90% of particles are less than or equal to the stated size) and d 100 is defined as the particle size at which the cumulative percentage undersize is 100 (i.e. the 100% of particles are less than or equal to the stated size).

Specific surface area is defined in units of square meters per gram (m2/gm). It is usually measured by nitrogen absorption analysis. In this analysis, nitrogen is absorbed on the surface of the substance. The amount of the absorbed nitrogen (as measured during the absorption or the subsequent desorption process) is related to the surface area via a formula known as the Brunauer Emmet Teller (B.E.T) formula.

The term "μιη" refers to "micrometer" which is lx 10"6 meter.

The tetrabenazine obtained from the present invention may be milled, sifted and / or micronized.

The crystalline form A of substantially pure tetrabenazine compound of structural formula I obtained from the present invention may be milled, sifted and / or micronized.

The crystalline form A of substantially pure tetrabenazine compound of structural formula I of defined particle size i.e. d90 equals to or less than 50μιη may be produced by milling of a feedstock material and sorting of the milled material by size.

The crystalline form A of substantially pure tetrabenazine compound of structural formula I may be multimilled through 0.5mm mesh sieve and may be sifted through 40 mesh sieve.

The pharmaceutical composition of substantially pure crystalline form A of Tetrabenazine compound of structural formula I obtained by the present invention may be formulated into solid dosage forms for administration to humans.

The solid dosage forms of substantially pure crystalline form A of Tetrabenazine compound of structural formula I may be oral tablets having 12.5mg and 25mg strength.

The solid dosage forms of substantially pure crystalline form A of Tetrabenazine compound of structural formula I may contain excipients selected from the group comprising of lactose, maize starch, talc, yellow iron oxide or magnesium stearate.

BRIEF DESCRIPTION OF THE FIGURES

Figure no. 1 X-Ray Powder Diffractogram of tetrabenazine crystalline form A

Figure no. 2 DSC thermogram of tetrabenazine crystalline form A

Figure no. 3 TGA thermogram of tetrabenazine crystalline form A

Method of analy

XRD:

Instrument: PANalytical X'pert PRO

X-ray source: Cu (1.5406A)

Filter for Κβ Nickel

Scanning range: 2-40° (2Θ)

DSC:

Instrument: DSC Q1000

Cell Constant: 1.1307

Ramp: 10.00°C/min to 170.00°C

Isothermal for 0.50 min

Gas Flow: Nitrogen 50.0 ml/min

TGA:

Instrument: TGA Q500

Ramp: 10.00°C/min to 350.00°C

Balance Gas: Nitrogen 10.0 ml/min

Sample Gas: Nitrogen 90.0 ml/min

The particle size distribution of Tetrabenazine may be determined by laser diffraction method.

Instrument : Malvern Mastersizer

Sample Handling Unit : Scirocco 2000

Air Pressure : 2.4 Bar

Feed Rate : 50%

Dispersant Name : Dry dispersion

Obscuration : 2.10%

The chemical purity of Tetrabenazine compound of structural formula I was measured by high performance liquid chromatography equipped with quaternary gradient pumps, variable wavelength UV detector attached with data recorder and integrator software under the following conditions:

Column : Reverse phase column CI 8

Flow rate : 1.0 ml/min.

Wavelength : 230 nm

Column Temperature : 40°C

Injection volume : 20 μΐ

Run time : 75 minutes

Sample cooler temperature : 10°C

Rinse/wash solvent : Mixture of 20 volumes of water and 80 volumes of acetonitrile

Mobile phase-A: Dibasic phosphate buffer solution (0.01M)

Mobile phase-B: A mixture of acetonitrile and methanol

Gradient Programme:

In the following section one preferred embodiment has been described by way of example to illustrate the process of the invention. However, it is not intended in any way to limit the scope of the present invention.

EXAMPLE: PROCESS FOR THE PREPARATION OF SUBSTANTIAL PURE CRYSTALLINE FORM A OF TETRABENAZINE

Stage A: Process for the preparation of 6, 7-dimethoxy-3, 4-dihydroisoquinoIine

Step 1 : Process for the preparation of N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine

A solution of 2-(3, 4-dimethoxyphenyl)-ethylamine (500gm) in toluene (2000ml) was added formic acid (150gm) at 25°C, the resulting reaction mixture was diluted with toluene (500ml) and heated up to 45°C. The reaction mixture was maintained at 40-45°C for 5 hours and then the resulting reaction mixture was concentrated under reduced pressure at 50°C to get the title compound

Yield: 570gm

Purity: 99.98% (By HPLC)

Step 2: Process for the preparation of 6, 7-dimethoxy-3, 4-dihydroisoquinoline

A solution of N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine (250gm) obtained from step 1 in toluene (500ml) and polyphosphoric acid (50gm) was heated at 110°C for 5 hours. The resulting reaction mixture was cooled to 50°C, quenched with water (500ml) and pH of the resulting solution was adjusted to about 8.3 with aqueous solution of sodium hydroxide [sodium hydroxide (690gm) + water (690ml)]. The resulting reaction mass was extracted by ethyl acetate (2 1250ml), dried over anhydrous sodium sulfate (50gm) and concentrated under reduced pressure to get 6, 7-dimethoxy-3, 4-dihydroisoquinoline (190gm).

Yield: 215gm

Purity: 99.67% (By HPLC)

Stage B: Process for the preparation of 3-((dimethylamino) methyi)-5-methylhexan-2-one methiodide

Step 1 : Process for the preparation of 3-((dimethylamino) methyl)-5-methylhexan-2-one

Dimethylamine hydrochloride (180gm) and paraformaldehyde (lOOgm) were added to a solution of 5-methylhexan-2-one (900ml) in methanol (1600ml). The resulting reaction mass was heated at reflux for 12 hours, and then the pH was adjusted to about 8.75 with aqueous solution of sodium hydroxide [sodium hydroxide(90gm) + water (900ml)] at 25 °C. The resulting reaction solution was extracted by toluene (2x1234ml). The organic layer was dried over anhydrous sodium sulfate (50gm) and concentrated under reduced pressure to get title compound.

Yield: 900gm

Purity: 99.80% (By HPLC)

Step 2: Process for the preparation of 3-((dimethylamino) methyl)-5-methylhexan-2-one methiodide

Methyl iodide (323gm) was added dropwise to a solution of 3-((dimethylamino) methyl)-5- methylhexan-2-one (195gm) obtained from step 1 , in ethyl acetate (1650ml) at 25-30°C in 30 minutes. The resulting reaction mixture was stirred at 25 °C for 12 hours and then the resulting solids were filtered, washed with water (200ml) and suck-dried to get wet compound (400gm). The wet compound was slurried with water (1000ml) at 25°C for 1 hour and then it was again filtered, washed with water (200ml) and dried at 45-50°C to get title compound

Yield: 300gm

Purity: 99.86% (By HPLC)

Stage C: Preparation of substantial pure crystalline form A of Tetrabenazine

3-((Dimethylamino) methyl)-5-methylhexan-2-one methiodide (80gm) was added to the solution of 6, 7-dimethoxy-3, 4-dihydroisoquinoline (40gm) in isopropanol (288ml) at 25°C and the resulting reaction mass was heated at 40-45°C for 15 hours. The resulting insoluble material was filtered, washed with isopropanol (80ml) and filtrate was concentrated under reduced pressure up to the 150ml reaction volume. The reaction solution was diluted with methylene dichloride (1200ml) and water (1000ml) and pH was adjusted to 8.5 with sodium hydroxide solution [10%, 100ml]. The organic layer was separated, washed with water (3 x 1000ml) and concentrated under reduced pressure to obtain residue. The residue was dissolved in methanol (300ml) at

50°C, and resulting solution was treated with an activated carbon (20gm) at 50-60°C for 30minutes and then it was filtered and filtrate was further stirred at 20-25°C for 2 hours. The resulting solids were filtered, washed with methanol (150ml), dried at 50-55°C for 8 hours. The resulting solids were milled, sifted through 40 mesh sieve and micronized.

Yield: 65gm

Purity: 99.96% (By HPLC)

X-ray Diffraction Pattern: As depicted by figure no. 1

DSC Thermogram: As depicted by figure no. 2

TGA Thermogram: As depicted by figure no. 3

Particle Size distribution:

dlO: 0.78 μιη

d50: 2.10 μιτι

d90: 4.47 μηι

dlOO: 7.37 μιη

Specific surface area of about 3.92 m2/g

While the present invention has been described in terms of its specific embodiments, certain modifications and equivalents will be apparent to those skilled in the art and are intended to be included within the scope of the present invention.

Claims

1. A process for the preparation of tetrabenazine compound of structural formula I comprises formylating 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III and converting N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into tetrabenazine compound of structural formula I.

Formula II Formula III Formula I

2. A process for the preparation of tetrabenazine compound of structural formula I comprising the steps of:

a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III,

Formula II Formula III b. converting N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII and

Formula III Formula VII c. converting 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII into tetrabenazine compound of structural formula I.

3. A process for the preparation of crystalline form A of substantially pure tetrabenazine compound of structural formula I comprising the steps of

a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III,

Formula II Formula III b. converting substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII,

Formula III Formula VII c. converting substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII into substantially pure tetrabenazine compound of structural formula I and

Formula VII d. isolating crystalline form A of substantially pure tetrabenazine compound of structural formula I.

4. A process for the preparation of 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII comprises the steps of:

a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III and

Formula II Formula III b. converting N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

Formula III Formula VII

5. A process for the preparation of N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III comprises reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III.

Formula II Formula III

6. A process for the preparation of substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII comprising the steps of:

a. reacting 2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula II with formic acid to get substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III and

Formula II Formula III

b. converting substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III into substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

Formula III Formula VII

7. The process according to claim nos. 1 to 6, wherein reaction of 2-(3, 4-dimethoxyphenyl)- ethylamine compound of structural formula II with formic acid is carried out in an aromatic hydrocarbon solvents.

8. The process according to claim no. 7 wherein aromatic hydrocarbon solvent is selected from the group comprising of toluene, o-xylene, p-xylene or mixture(s) thereof.

9. The process according to claim nos. 1 to 6, wherein reaction of 2-(3, 4-dimethoxyphenyl)- ethylamine compound of structural formula II with formic acid is carried out for a period of 2 hours to 10 hours at a temperature in the range of 40°C to 150°C.

10. A substantially pure N-formyl-2-(3, 4-dimethoxyphenyl)-ethylamine compound of structural formula III having less than 0.15% weight / weight of following compounds of structural formula XV

11. The process according to claims nos. 2, 3, 4 or 6 wherein N-formyl-2-(3, 4- dimethoxyphenyl)-ethylamine compound of structural formula III is reacted with polyphosphoric acid to get a 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII.

12. A substantially pure 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII having less than 0.15% weight / weight of following compounds of structural formula IX, X, XXIII, XXIV, XXV and XXVI.

13. The process according to claim no. 2 or 3 wherein 6, 7-dimethoxy-3, 4-dihydroisoquinoline compound of structural formula VII is reacted with 3-dimethylamino methyl-5-methyl-hexan-2- one methiodide compound of structural formula VIII to get a tetrabenazine compound of structural formula I.

14. The process according to claim no. 13 wherein reaction of 6, 7-dimethoxy-3, 4- dihydroisoquinoline compound of structural formula VII with 3-dimethylaminomethyl-5-methyl- hexan-2-one methiodide compound of structural formula VIII is carried out for a period of 8 hours to 20 hours at a temperature in the range of 35°C to 120°C in an alcoholic solvents.

15. The process according to claim no. 14 wherein alcoholic solvent is selected from the group comprising of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, tertiary butanol, n-pentanol or mixture(s) thereof.

16. The process according to claim no. 3 wherein crystalline form A of substantially pure tetrabenazine compound of structural formula I is isolated by recrystallization of tetrabenazine compound of structural formula I in an alcoholic solvents.

17. The process according to claim no. 16 wherein alcoholic solvent is selected from the group comprising of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, tertiary butanol, n-pentanol or mixture(s) thereof.

18. A process of preparing crystalline form A of substantially pure tetrabenazine compound of structural formula I comprises recrystallization of tetrabenazine compound of structural formula I in an alcoholic solvents.

19. A pharmaceutical composition comprising crystalline form A of tetrabenazine compound of structural formula I and pharmaceutically acceptable carrier.

20. A substantially pure tetrabenazine having less than 0.15% weight / weight of compounds of structural formula XI, XII, XIII, XIV, XV, XVI, XXVII, XXVIII and XXIX.

21. A process for the preparation of substantially pure tetrabenazine having less than 0.1 % weight / weight of compounds of structural formula XI, XII, XIII, XIV, XV, XVI, XXVII, XXVIII and XXIX comprising the steps of:

a. treating the solution of crude tetrabenazine compound of structural formula I in an organic solvent with an aqueous solution of an alkali metal hydroxide,

b. washing. the organic layer with water,

c. concentrating the organic layer under reduced pressure to obtain residue and

d. treating the residue with an alcoholic solvent.

22. The process according to claim no. 21 wherein organic solvent is selected from the group comprising of ether solvents such as diethyl ether, n-propyl ether, n-butyl ether, methyl ethyl ether, methyl tertiary butyl ether, diisopropyl ether or mixture(s) thereof or halogenated hydrocarbon solvents such as dichloromethane, dichloroethane, carbon tetrachloride or chloroform.

23. The process according to claim no. 21 wherein the solution of crude tetrabenazine compound of structural formula I in an ether solvent is treated with an aqueous solution of an alkali metal hydroxide at a temperature in the range of 25 °C to 30°C for a period of 15 minutes to 1 hour and then organic layer may be isolated.

24. The process according to claim nos. 21 and 23 wherein alkali metal hydroxide is selected from the group comprising of sodium hydroxide, potassium hydroxide or lithium hydroxide.

25. The process according to claim no. 21 wherein alcoholic solvent is selected from the group comprising of methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, tertiary butanol, n-pentanol or mixture(s) thereof.

26. A substantially pure tetrabenazine compound of structural formula I having less than 0.15% weight / weight of compounds of structural formula XXVII, XXVIII and XXIX.

27. A pharmaceutical composition comprises substantially pure tetrabenazine compound of structural formula I having more than 99.5 % purity as determined by HPLC technique and optionally one or more other substances such as pharmaceutical excipients.

28. A pharmaceutical composition comprises crystalline form A of substantially pure tetrabenazine compound of structural formula I having bulk density in the range of 0.10gm/ml to 0.60gm/ml and optionally one or more other substances such as pharmaceutical excipients.

29. A pharmaceutical composition comprises crystalline form A of substantially pure tetrabenazine compound of structural formula I having tapped density in the range of 0.30gm/ml to 0.70gm/ml and optionally one or more other substances such as pharmaceutical excipients.

30. A pharmaceutical composition comprises crystalline form A of substantially pure tetrabenazine compound of structural formula I having d90 equals to or less than 50μιη and optionally one or more other substances such as pharmaceutical excipients.

31. A pharmaceutical composition comprises crystalline form A of substantially pure tetrabenazine compound of structural formula I having surface area in the range of 2.0 m /gm to 6.0 m /gm and optionally one or more other substances such as pharmaceutical excipients.

32. The pharmaceutical composition of claim nos. 27 to 31 , wherein pharmaceutical excipients is selected from the group comprising of lactose, maize starch, talc, yellow iron oxide or magnesium stearate.

33. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by X-ray diffraction pattern having following peaks:

34. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of powder X-ray diffraction pattern having peaks at 6.4, 10.7, 12.1, 12.9, 14.3, 19.8, 22.2 and 23.2 ± 0.2° 2Θ.

35. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of bulk density in the range of O.lOgm/ml to 0.60gm/ml.

36. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of tapped density in the range of 0.30gm/ml to 0.70gm/ml.

37. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of surface area in the range of 2.0 m2/gm to 6.0 m2/gm.

38. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of d90 equals to or less than 50μιτι.

39. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of powder X-ray diffraction pattern as depicted by figure no. 1.

40. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of DSC thermogram as depicted by figure no. 2.

41. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of TGA thermogram as depicted by figure no. 3.

42. The crystalline form A of substantially pure tetrabenazine compound of structural formula I having less than 0.15% weight / weight of compounds of structural formula XXVII, XXVIII and XXIX.

43. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of DSC thermogram having peak at more than 120°C

44. The crystalline form A of substantially pure tetrabenazine compound of structural formula I characterized by data selected from a group consisting of DSC thermogram having peak at 129.14°C ± 5°C.

45. A tetrabenazine compound of structural formula I characterized by one of the following analytical data:

HPLC purity having equals to or more than 99.5 %; Bulk density in the range of 0.1 Ogm/ml to 0.60gm/ml; Tapped density in the range of 0.30gm/ml to 0.70gm/ml; Surface area in the range of 2.0 m /gm to 6.0 m /gm or d90 equals to or less than 50μηι.

46. A pharmaceutical composition comprises tetrabenazine compound of structural formula I having bulk density in the range of 0.1 Ogm/ml to 0.60gm/ml and optionally one or more other substances such as pharmaceutical excipients.

47. A pharmaceutical composition comprises tetrabenazine compound of structural formula I having tapped density in the range of 0.30gm/ml to 0.70gm/ml and optionally one or more other substances such as pharmaceutical excipients.

48. A pharmaceutical composition comprises tetrabenazine compound of structural formula I having d90 equals to or less than 50μιιι and optionally one or more other substances such as pharmaceutical excipients.

49. A pharmaceutical composition comprises tetrabenazine compound of structural formula I having surface area in the range of 2.0 m2/gm to 6.0 m2/gm and optionally one or more other substances such as pharmaceutical excipients.

50. The pharmaceutical composition of claim nos. 46 to 49, wherein pharmaceutical excipients is selected from the group comprising of lactose, maize starch, talc, yellow iron oxide or magnesium stearate.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN3414/MUM/2010 | 2010-12-15 | ||

| IN3414MU2010 | 2010-12-15 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012081031A1 true WO2012081031A1 (en) | 2012-06-21 |

Family

ID=44504049

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/IN2011/000247 WO2012081031A1 (en) | 2010-12-15 | 2011-04-11 | Process for preparing tetrabenazine |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2012081031A1 (en) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103965108A (en) * | 2013-02-06 | 2014-08-06 | 公安部禁毒情报技术中心 | Synthetic method for laudanine |

| WO2015084622A1 (en) | 2013-12-03 | 2015-06-11 | Auspex Pharmaceuticals, Inc. | Methods of manufacturing benzoquinoline compounds |

| US9233959B2 (en) | 2012-09-18 | 2016-01-12 | Auspex Pharmaceuticals, Inc. | Formulations and pharmacokinetics of deuterated benzoquinoline inhibitors of vesicular monoamine transporter 2 |

| US9550780B2 (en) | 2012-09-18 | 2017-01-24 | Auspex Pharmaceuticals, Inc. | Formulations pharmacokinetics of deuterated benzoquinoline inhibitors of vesicular monoamine transporter 2 |

| CN110143889A (en) * | 2019-06-26 | 2019-08-20 | 江苏暨明医药科技有限公司 | A kind of synthetic method of 3- [(dimethylamino) methyl] -5 methy 12 hexanone |

| CN110698397A (en) * | 2019-10-28 | 2020-01-17 | 南京红杉生物科技有限公司 | Tetrabenazine intermediate, and synthesis method, application and intermediate product for synthesis thereof |

| CN110845410A (en) * | 2019-10-29 | 2020-02-28 | 暨明医药科技(苏州)有限公司 | Method for preparing 6, 7-dimethoxy-3, 4-dihydroisoquinoline hydrochloride by one-pot method |

| US10632107B2 (en) | 2018-05-14 | 2020-04-28 | Apotex Inc. | Crystalline forms of benzoquinoline inhibitors of vesicular monoamine transporter 2 |

| US11179386B2 (en) | 2017-03-15 | 2021-11-23 | Auspex Pharmaceuticals, Inc. | Analogs of deutetrabenazine, their preparation and use |

| US11357772B2 (en) | 2015-03-06 | 2022-06-14 | Auspex Pharmaceuticals, Inc. | Methods for the treatment of abnormal involuntary movement disorders |

| WO2023159040A1 (en) * | 2022-02-15 | 2023-08-24 | Foresee Pharmaceuticals Co., Ltd. | Crystalline (+)-tetrabenazine |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2830993A (en) | 1958-04-15 | Quinolizine derivatives | ||

| EP0154842A2 (en) * | 1984-03-03 | 1985-09-18 | Dr. Karl Thomae GmbH | Medicament containing quaternary 3,4-dihydroisoquinoline salts |

| WO1994000460A1 (en) * | 1992-06-25 | 1994-01-06 | The Regents Of The University Of California | SYNTHESIS OF N-FORMYL-3,4-DI-t-BUTOXYCARBONYLOXY-6-(TRIMETHYLSTANNYL)-L-PHENYLALANINE ETHYL ESTER AND ITS REGIOSELECTIVE RADIOFLUORODESTANNYLATION TO 6-[18F]FLUORO-L-DOPA |

| WO2008058261A1 (en) * | 2006-11-08 | 2008-05-15 | Neurocrine Biosciences, Inc. | Substituted 3-isobutyl-9, 10-dimethoxy-1,3,4,6,7,11b-hexahydro-2h-pyrido[2,1-a] isoquinolin-2-ol compounds and methods relating thereto |

| WO2008154243A1 (en) * | 2007-06-08 | 2008-12-18 | General Electric Company | Method for making tetrabenazine compounds |

| WO2010044981A2 (en) * | 2008-09-18 | 2010-04-22 | Auspex Pharmaceutical ,Inc. | Benzoquinoline inhibitors of vesicular monoamine transporter 2 |

-

2011

- 2011-04-11 WO PCT/IN2011/000247 patent/WO2012081031A1/en active Application Filing

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2830993A (en) | 1958-04-15 | Quinolizine derivatives | ||

| EP0154842A2 (en) * | 1984-03-03 | 1985-09-18 | Dr. Karl Thomae GmbH | Medicament containing quaternary 3,4-dihydroisoquinoline salts |

| US4678792A (en) | 1984-03-03 | 1987-07-07 | Dr. Karl Thomae Gmbh | Quaternary 3,4-dihydro-isoquinolinium salts |

| WO1994000460A1 (en) * | 1992-06-25 | 1994-01-06 | The Regents Of The University Of California | SYNTHESIS OF N-FORMYL-3,4-DI-t-BUTOXYCARBONYLOXY-6-(TRIMETHYLSTANNYL)-L-PHENYLALANINE ETHYL ESTER AND ITS REGIOSELECTIVE RADIOFLUORODESTANNYLATION TO 6-[18F]FLUORO-L-DOPA |

| WO2008058261A1 (en) * | 2006-11-08 | 2008-05-15 | Neurocrine Biosciences, Inc. | Substituted 3-isobutyl-9, 10-dimethoxy-1,3,4,6,7,11b-hexahydro-2h-pyrido[2,1-a] isoquinolin-2-ol compounds and methods relating thereto |